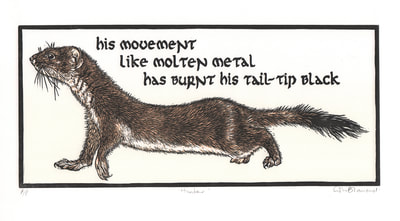

With many of my prints in the past, I have made multiple ‘reduction’ stencils; by leaving the screen locked in register and gradually working on one stencil to produce several tones of one colour range; before making the reduction stencil for the next colour range of the print – and so on.

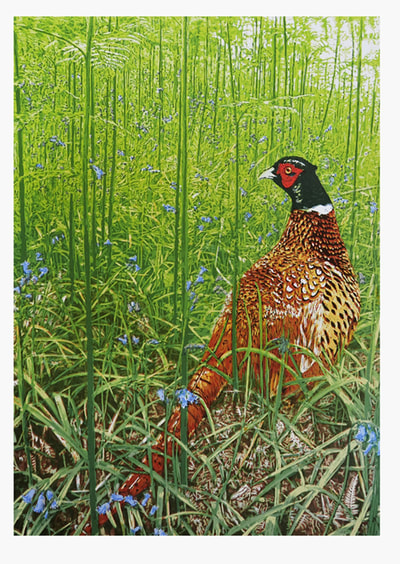

Quite complex images can be created this way. This print 'Late May' used something approaching 30 different stencils – many with blended multiple colour inks.

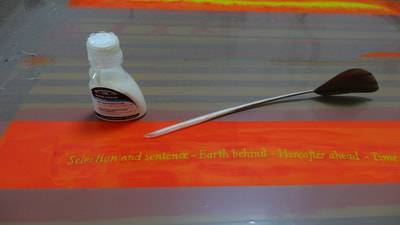

My latest print ‘Crucial Pause’ was made entirely with hand painted stencils in this way; building up the image with around thirty layers of ink in varying transparencies. For the text I used art masking fluid - applied to the mesh first, then painted over with filler and the masking fluid rubbed off to create the stencil.

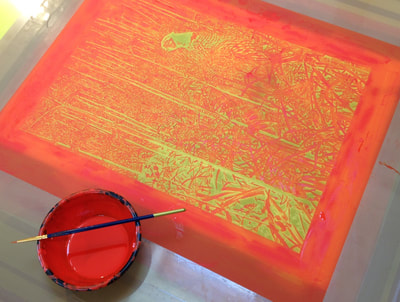

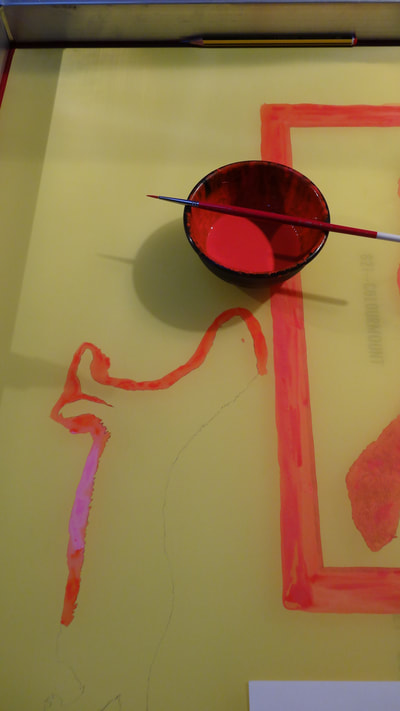

Since I converted to ‘non toxic’ screen inks (which I have to say are much better in many other ways too) the screen filler I have been using is this bright orange stuff, made by Lascaux.

Now – the main problem with this stuff is its very efficiency. Once even a trace of it is in the mesh and has dried, it’s there pretty much for good! Make a mistake when painting a stencil on a screen that cannot be moved from its registered position, and the only solution is a laborious scrubbing and dabbing with a strong spirit solvent.

When the stencils are finished with and the screen needs to be reclaimed, I have to use solvent ‘screenwash’ and a pressure washer. Lascaux do sell a remover which is very expensive and doesn’t work as well. As for the advice to use household surface cleaner…simply forget it!

I do feel uncomfortable still having to use chemical solvents. But what sets my mind at rest is that I believe that (apart from some initial potential danger to me) the nature of my screenwash means that our ‘soak away’ drain system (my studio is in old farm buildings) breaks down the washed off solution before it enters the water catchment; unlike many ordinary household chemicals and cleaners washed down main drains.

To date I have tried one alternative to the Lascaux filler, and that is the ‘System 3 Removeable Screen Block’ made by Daler Rowney. I have to report that the word “removeable” is very accurate!

I wasted a whole afternoons work. I proofed a stencil I'd painstakingly painted, then cleaned out the ink as normal.....and the damn filler just washed off the screen too! Admittedly I use very fine meshes (120 and 140 but properly degreased etc) and I do thin the filler with water as described. But I have no problem whatsoever with the Lascaux product when I do this. I can only imagine that they have only tested their filler when used very thickly on coarser mesh.

I am interested to hear if anyone else has tried anything else for this method of stencil making?

RSS Feed

RSS Feed