I apologise for its complexity of explanation in places. I’ve tried to simplify but I know some people will be interested. And never did know when to stop!

As always – even these little things needed some preparatory drawing. I believe it is the essential basis of much printmaking – especially linocut, to allow ones brain to explore the image in detail first; before beginning to carve. Of course some lino printers work every part of the block out first and then simply remove the non-image areas. Of course, with things like text, I do this too, But most often, I like to ‘draw’ the image with the gouges. And I find to do that I need the almost subconscious preparation of having already translated the source material into graphic form – albeit initially in tones. For one of these prints I had a hare drawing already prepared, but decided she was a bit serious looking, so I drew another.

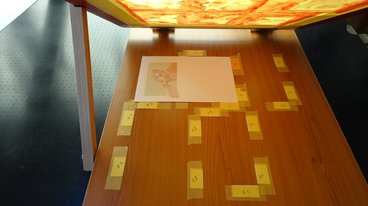

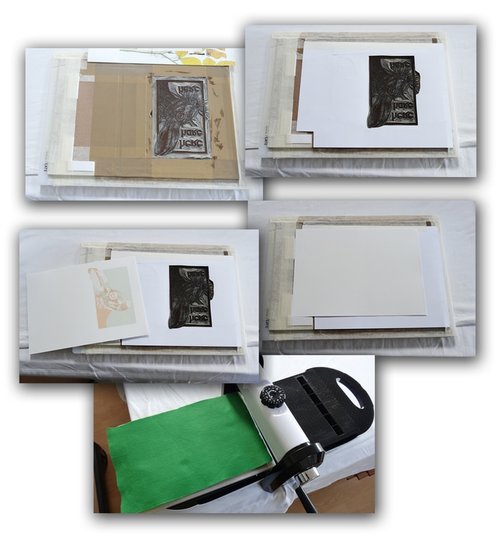

It is my habit now to print on the XCut in one direction only - from left to right, handle turning clockwise. And I tend to register to the farthest edge of the paper; believing the card stops to help keep the paper in position. Of course, with the Ternes Burton pin system the other edge is used, as the tabs help stop paper drag as it goes through the rollers.

I later flipped the block around 180 degrees, to how it is shown in this pic, so it was still printing in the correct place to make a greeting card, but this allowed the block to pass under the rollers first – thus reducing the risk of paper movement and mis-register.

First I bought a pair of these https://goo.gl/17NOgV on EBay. Less than a tenner including delivery. OK I had to wait for them to come from Hong Kong, but they looked sturdier in the pictures than some others I had seen. And so it proved. They seem remarkably well made and efficient for the price.

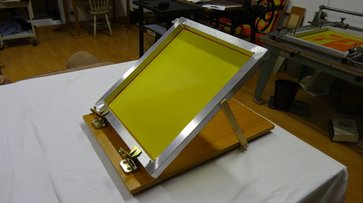

The screen is a 140t mesh 30mm aluminium section and the base board is a ‘re-purposed’ bit of old kitchen unit melamine surfaced chipboard, with a prop and support made from offcuts.

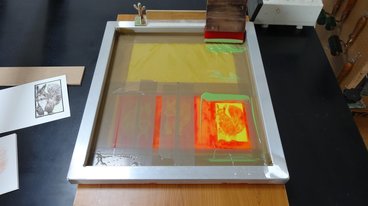

The results were even better than I hoped. Sometimes I had to just wait half a second for the paper to drop back to the bed before lifting the screen and doing the ‘flood’ stroke, but overall a perfect result. It will be interesting to see if larger areas of flat colour will be just as successfully screen printed without a vacuum.

And so a few sheets of 300gsm paper for each image were proofed with three carefully planned colours of transparent screen ink, which also overprinted each other in places to produce extra tones.

Two different but more subtle dark browns of Caligo Safewash were mixed for the key blocks and a mask cut to keep the margins clean (note the use of vinyl tape on the ‘forme’ made to fix the block’s position. This makes for easier clean up). The same lay edge goes into the card stops and away it went through the press.

RSS Feed

RSS Feed