My latest project followed hard on the heels of my earlier experiments with the little XCut Xpress and simple home made non-vacuum portable screen printing beds. I had already combined the XCut’s effective printing of lino with the speed and versatility of hand painted screen print stencils to apply or underprint colour; but only on a small scale. When doing so, I had also experimented with using the very effective Ternes Burton pin and tab system to accurately register both methods of printing on the same image.

Just a note on these TB pins: Made initially, I believe, for registering the overlaying of pre digital animation ‘cells’, they are made and sold here https://www.ternesburton.com/

However the enterprising Shirley at ‘Handprinted’ printmaking suppliers in the UK will supply both pins and tabs at a very reasonable rate http://www.handprinted.co.uk/printmaking/relief-printmaking/tools/ternes-burton-registration-pins-pair

Although a little tedious to apply and set up initially, they are wonderful at keeping accurate registration of multiple colour linocuts; particularly on roller type presses where there is a tendency for the pressure to shift the paper.

They work by attaching thin plastic tabs to each sheet to be printed. These then clip neatly on to metal pins which are fixed in constant position relative to the block.

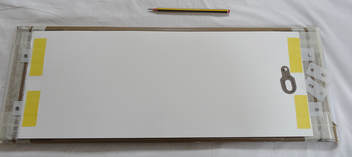

Most people use just two pins and tabs. This is fine for small scale, squarish images. However for larger – or rather, proportionally longer images (such as I make on the XCut Xpress) I have found it necessary to add a third set on the ‘furthest’ edge, in order to prevent any sideways twisting of the paper as it goes through the press. In the picture below right you will see I have actually attached four pins and tabs - for reasons i will explain later.

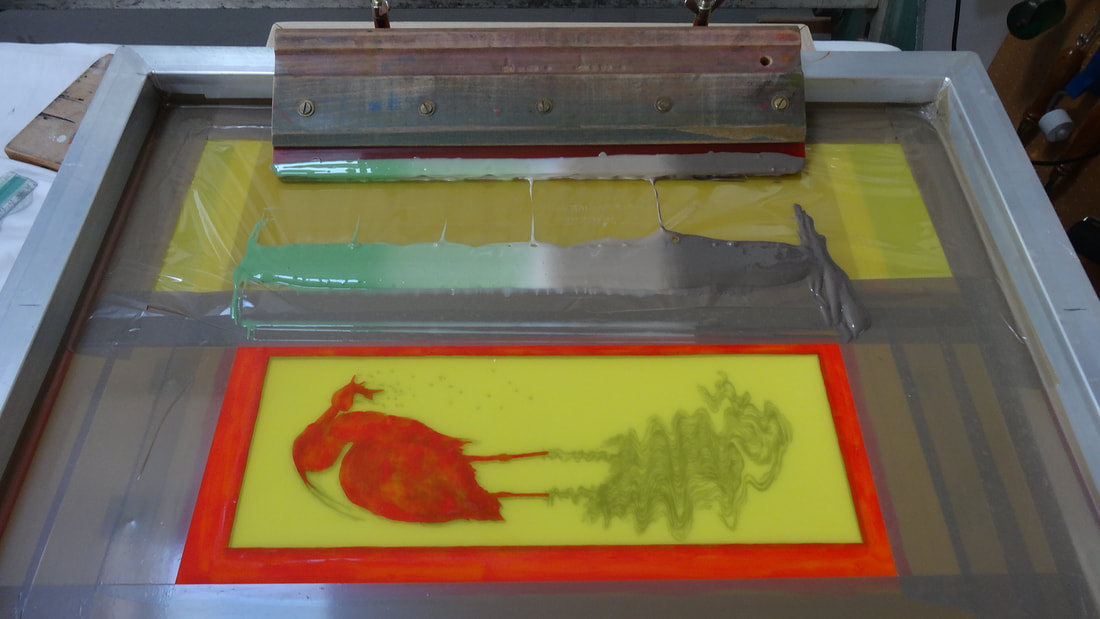

One of the potential problems with screen printing without a vacuum pump to hold the paper flat to the bed, is that the natural tackiness of the screen ink will tend to temporarily adhere the printed sheet to the underside of the screen mesh when the screen is lifted. Although it is possible to simply peel off the printed paper (before flood coating the stencil again) this is tedious and can smudge the edges of the image. In fact, the printing of crisp fine detail to a high and consistent standard through a screen stencil requires each piece of the stencil to only be in contact with the paper for the split second the sharp edge of the squeegee is ‘cutting’ the layer of ink from the open mesh areas down on to the surface to be printed. The mesh should ‘snap’ away immediately and cleanly from the paper as the squeegee passes.

Screening small areas of ink is not too much of a problem – especially printing on heavier papers. However, stencils with large flat areas - which may cover much of the paper - are tricky, even on the heavyish 300gsm paper I tend to use.

Some people have used a light spray of glue on the bed of the non-vacuum press to overcome the problem. Personally do not want to be trying to stack and handle prints with a gluey reverse side, or have to remount each print on a suitable support paper before sale.

It helps somewhat to print with fine meshes; which means less ink deposited with each flood and pull and therefore less ‘tack’. I am in fact in the process of re stretching most of my screens with 140T mesh (having been used to using 90T from the old days of smelly oil based inks, which dried in and blocked the mesh more easily on very fine meshes) as I find other advantages when using modern water based inks.

TB pins instead of a vacuum?

I talked a little about this particular print of Hern the heron in my last blog post. And I have to say, that although I did produce a second version, the first one don’t look too bad now! Part of the plan all along with this print was to further develop the capabilities of my ‘table top’ equipment; utilising the maximum print size of the XCut . But I also wanted to try and use the TB pins and tabs system to actually hold the paper down, in position, in the absence of a vacuum.

As long as the underside of the screen mesh is protected, with a little pad of tape from potential damage from the edge of the metal pin if the squeegee runs over it, the TB system is just as accurate, if slower, than the conventional flat 'stops' or 'tabs' I usually use for registration when screen printing.

The method

RSS Feed

RSS Feed