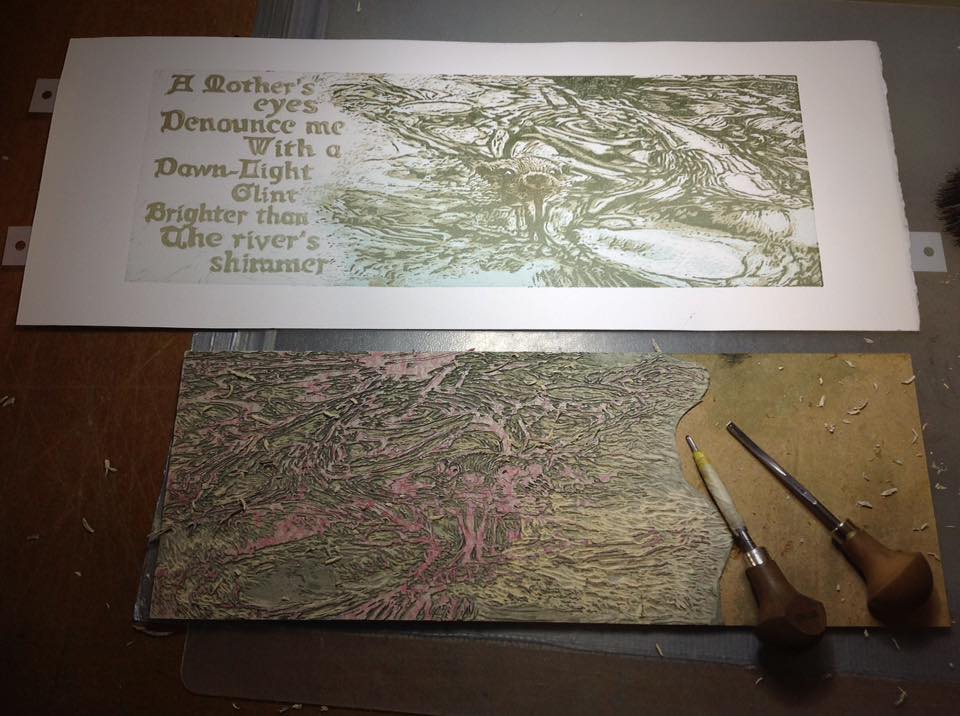

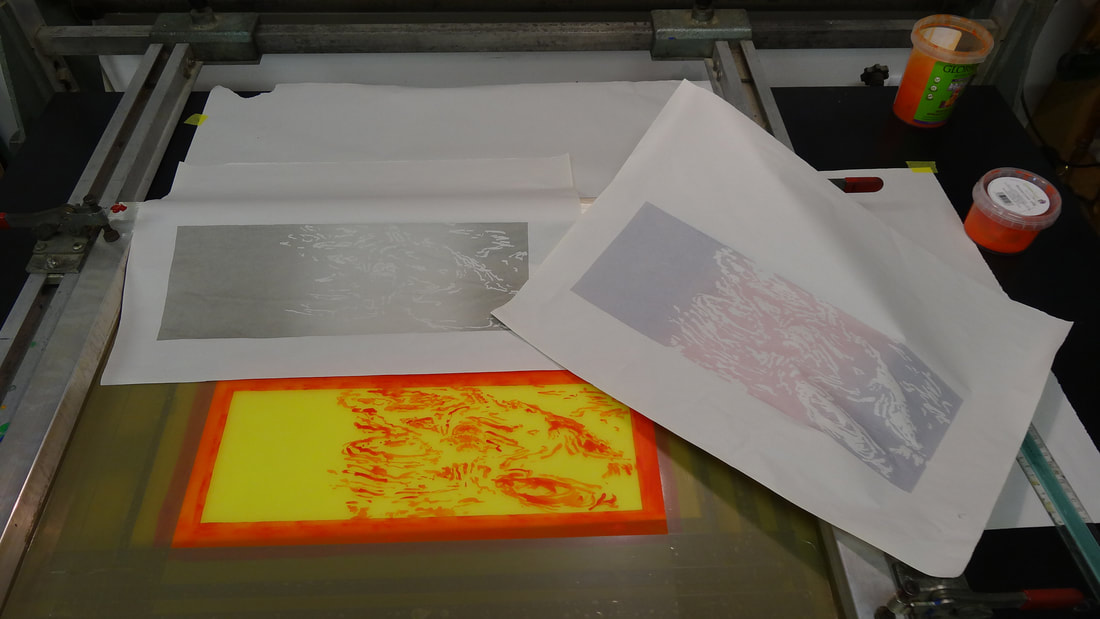

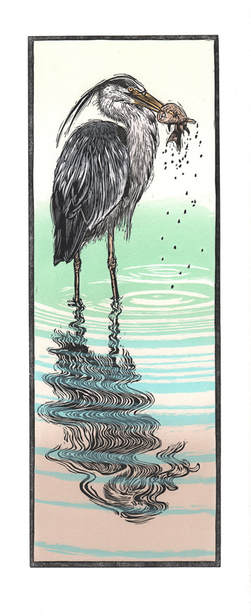

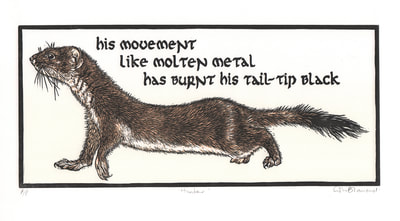

I have written before about my preference for using Marmoleum commercial flooring lino for my linocuts. It is a little thinner but much firmer than anything else available; crisper and more durable, but still carves like butter when warm. It does require some preparation before use, but like many similar tasks in printmaking, I have to say I quite enjoy the process of turning a sheet of flooring into a lovely firm prepared printing block.

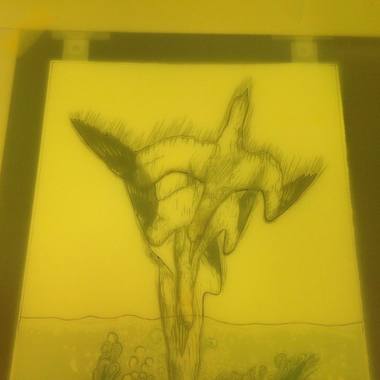

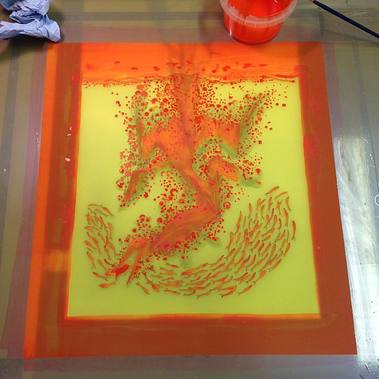

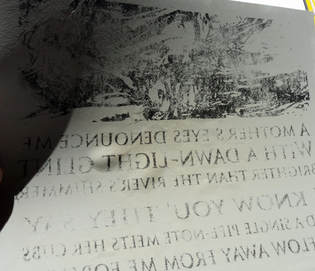

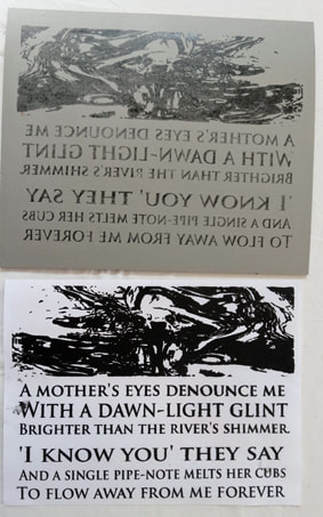

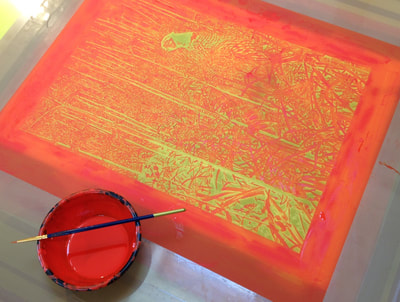

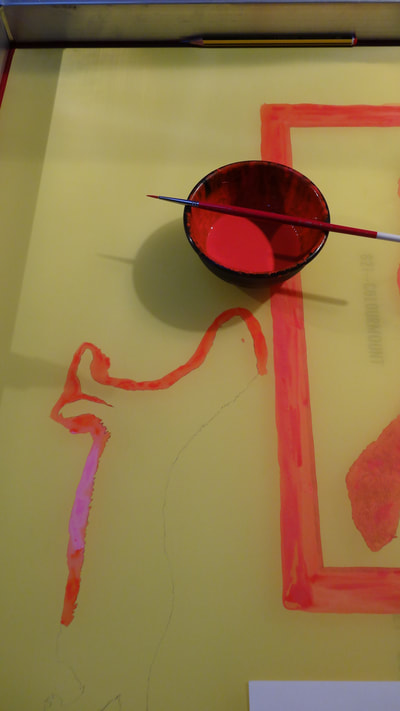

I like a light coloured lino (white would be good, but they don’t make it); the surface of which I can stain (usually red). This is in order to be able to both draw on the surface with pen and pencil and then be able to clearly see the cut marks I make in positive - i.e. how they will print.

Two years ago I bought, via my local carpet shop, a 2m wide roll of the then palest cream colour Marmoleum I could find. I chopped it into large pieces and stored it flat. I have now used nearly all of this and the remaining pieces seem to have begun to harden; which of course will happen if stored where the linseed oil used to make it can dry out.

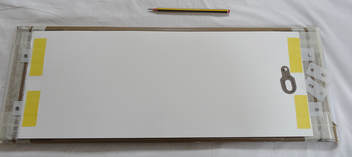

An initial search showed that in the meantime, Forbo the international company that manufactures Marmoleum, had not surprisingly, updated their range. Forbo and their suppliers are very good at providing samples, so after a little research I ended up with four pieces of the palest colours I could find. They were: Real ‘Edelweiss’; Concrete ‘Moon’; Walton ‘Titanium’; Fresco ‘Moonstone’.

I had cut the generously sized samples into four small blocks (small enough to also enable me to test another little ‘mini press’ I’ve been asked to look at – watch this space!)

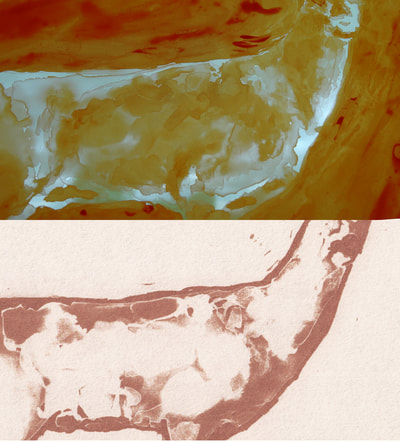

I mounted these on to 3mm hardboard/Masonite with carpet spray glue.

The two best both have a slight ‘ripple’ colour to them; whereas the ‘Titanium’ is plain. This makes no difference at all when carving. All have a slightly darker under-layer, which is useful as a guide to your depth of carving.

So the verdict?

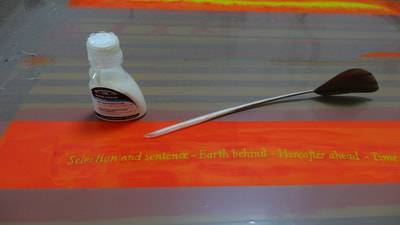

- ‘Real’ range ‘Edelweiss’ Code: 3257

- ‘Concrete’ range ‘Moon’ Code: 370135

- ‘Walton’ range ‘Titanium’ Code: 336935

- ‘Fresco’ range ‘Moonstone’ Code: 3883

P.S.

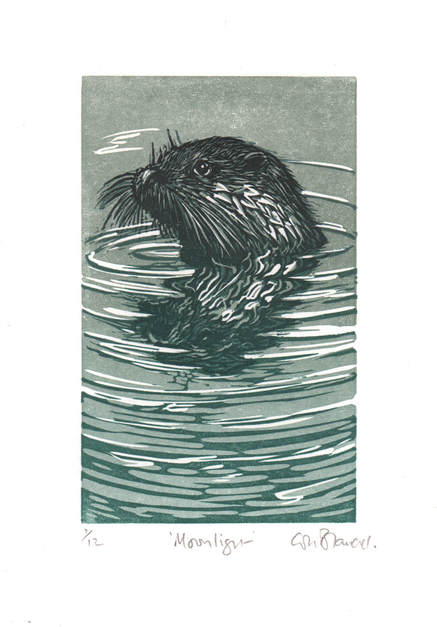

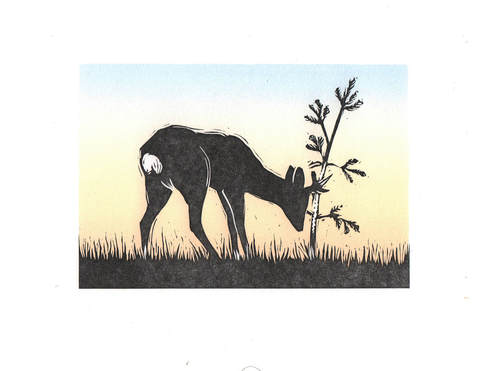

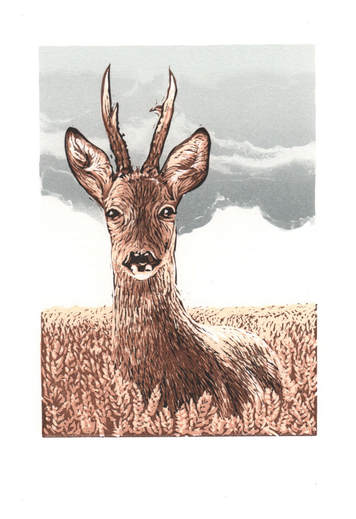

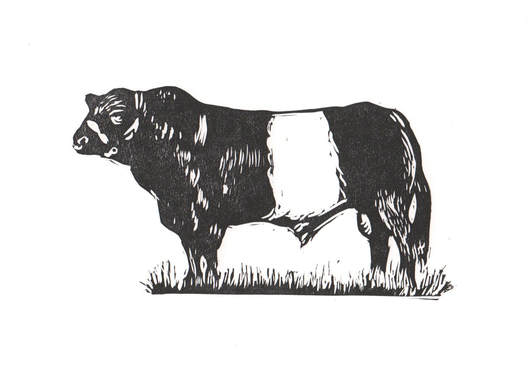

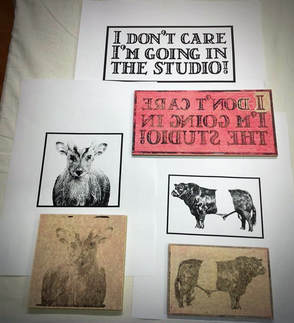

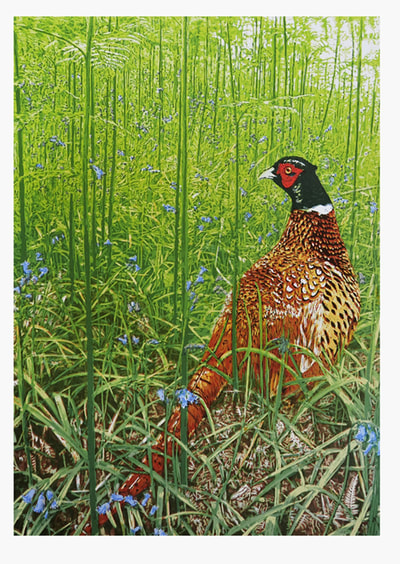

I am still in the process of making a small edition from these four little blocks, which will appear in due course!

RSS Feed

RSS Feed